Woodworking ERP First Thoughts

Published on 05 Jan 2023

I want to build a very simple ERP (Enterprise Resource Planning) tool for my home-based woodworking.

Context

I have a setup at home to work with reclaimed lumber, which suffers from various defects:

- Warping

- Cupping

- Bowing

- Rough edges

- Rough faces

- Embedded metal, i.e. nails or screws

- Dirt, concrete, or old finish

In order to work with this lumber, I need to process each board such that it will satisfy the following conditions:

- Straight, parallel edges

- Planed, parallel faces

- Clean surface

- No embedded metal

Specifications

Primary Application

- Keep an inventory of rough, reclaimed lumber.

- Record the changes in cleaning up and straightening the rough lumber.

- Record the products that are created from the lumber.

Secondary Application

- Keep track of machines

- Keep track of tools, both hand tools and power tools

- Keep track of consumables, e.g. screws

Initial Development

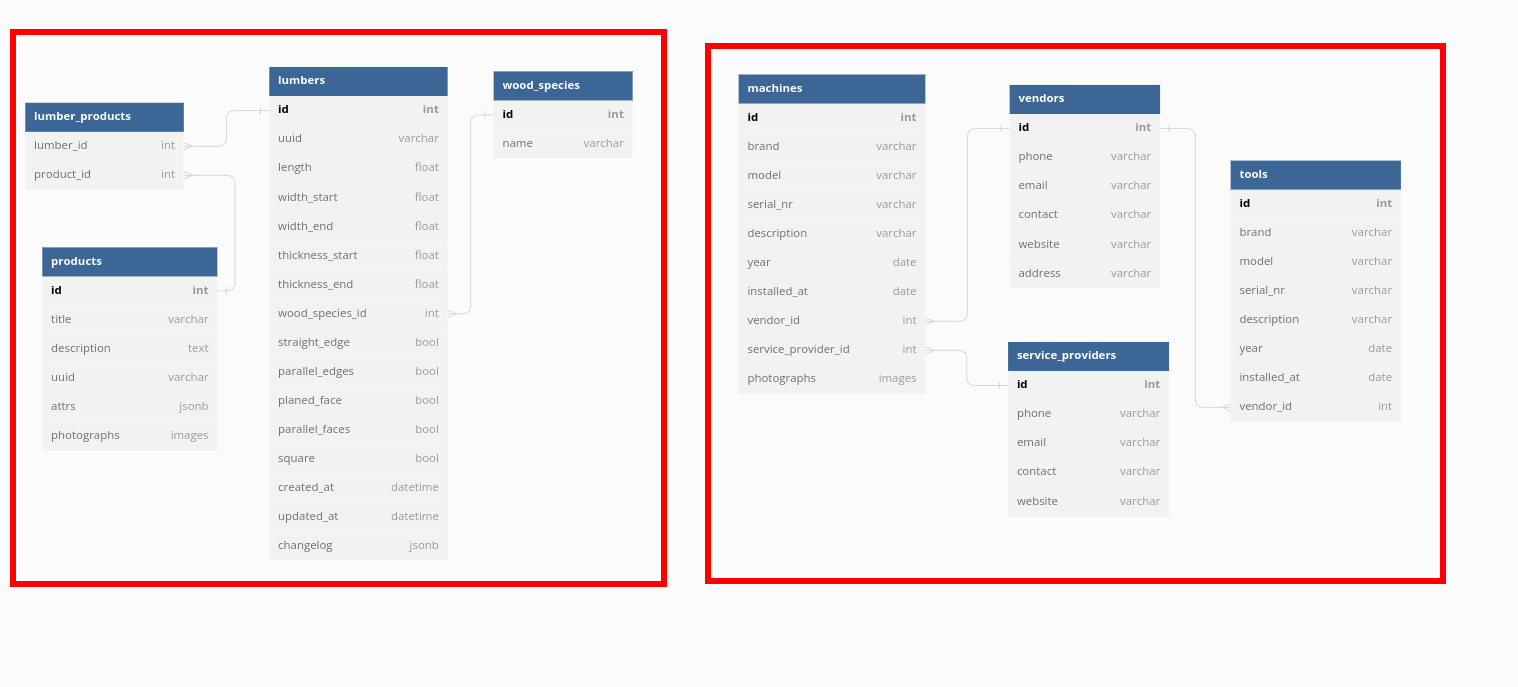

The central Model is the Lumber, which contains the following attributes:

| Attribute | Type | Description |

|---|---|---|

| uuid | string | A barcode generated in advance, printed, and applied to each board |

| length | float | Initially the length of the rough board |

| width_start, width_end | float | Width measured at each end, can differ on a skew board |

| thickness_start, thickness_end | float | Thickness measured at each end, can differ on a tapered board |

| wood_type | reference | Reference to the WoodType model |

| straight_edge | boolean | Whether the straight-edge jig has been used |

| parallel_edges | boolean | Whether the opposite edge has been cut using the straight-edge as a reference |

| planed_face | boolean | Whether the planing jig has been used |

| parallel_faces | boolean | Whether the opposite face has been planed using the planed face as a reference |

| square | boolean | Whether all sides in all directions are square, i.e. whether the board is ready to be used |

| timestamps | datetime | created_at and updated_at |

| changelog | jsonb | A JSON Array of Objects, each one containing all of the above attributes and a timestamp, to allow changes to be tracked |

The Lumber model has the following relationships:

belongs_to :barcodebelongs_to :wood_typebelongs_to :product, through: :lumber_products

Workflow

- Generate a mass of Barcode records, where the UUID is translated into a barcode.

- Print the barcodes, to have on hand.

- Attach a barcode to each board of reclaimed lumber

- In the

lumbercreate form, enter the board’s attributes along with the barcode - Use the barcode to bring up the

lumberedit form to update attributes during or after processing.